The manufacturing process of 247Garden's ERA Schedule 40 (SCH40) and Schedule 80 (SCH80) PVC (Polyvinyl Chloride) valves involves several key steps, each ensuring the final product meets specific pressure ratings and dimensional standards. Here is a detailed overview of the process:

1. Material Selection and Preparation

- Raw Materials: High-quality PVC resin is used as the primary material. Additives like stabilizers, plasticizers, lubricants, and pigments are mixed with the resin to achieve desired properties.

- Blending: The raw materials are thoroughly mixed in large blenders to create a homogeneous compound.

2. Molding Process

- Injection Molding: The blended PVC compound is fed into an injection molding machine. The material is heated to a molten state and injected into molds shaped like the valve components (body, seals, stem, etc.).

- Cooling and Solidification: The mold is cooled, usually by circulating water, causing the PVC to solidify into the desired shapes.

3. Machining and Finishing

- Trimming and Deburring: Excess material (flash) from the molding process is trimmed off, and any rough edges are smoothed.

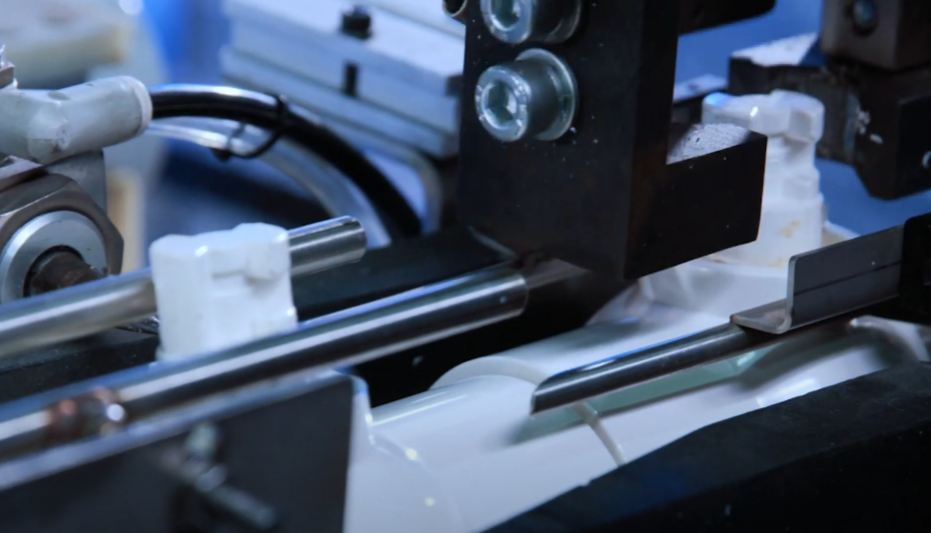

- Machining: Precision machining is performed on the molded parts to ensure tight tolerances and proper fit of the valve components.

4. Assembly

- Component Assembly: The molded and machined components are assembled. This includes fitting the valve body, stem, seats, seals, and handle.

- Sealing: Rubber or elastomer seals are installed to ensure leak-proof operation. These seals are often made from materials like EPDM (ethylene propylene diene monomer) or FKM (fluoroelastomer).

5. Quality Control and Testing

- Pressure Testing: Each valve is subjected to pressure testing to ensure it can handle the rated pressure for SCH40 or SCH80 specifications. SCH80 valves are tested to withstand higher pressures compared to SCH40 valves.

- Leak Testing: Valves are tested for leaks under both positive and negative pressures.

- Dimensional Inspection: All critical dimensions are checked to ensure they meet industry standards.

6. Surface Finishing and Marking

- Surface Treatment: The valve surfaces are treated to improve durability and resistance to chemicals and UV radiation.

- Marking: Each valve is marked with relevant information, such as size, pressure rating, material, and manufacturing date. This is typically done using inkjet printing or laser engraving.

7. Packaging and Distribution

- Packaging: Valves are cleaned, packed, and labeled according to customer and regulatory requirements.

- Distribution: Packaged valves are shipped to distributors, retailers, or directly to customers.

Differences Between SCH40 and SCH80 Valves

- Wall Thickness: SCH80 PVC valves have thicker walls compared to SCH40 valves, allowing them to handle higher pressures.

- Pressure Rating: SCH80 valves are designed for higher pressure applications, while SCH40 valves are used for lower pressure systems.

- Color: Often, SCH40 PVC is white, and SCH80 PVC is gray, but this can vary by manufacturer.

By adhering to these processes and standards, manufacturers ensure that SCH40 and SCH80 PVC valves are reliable, durable, and meet the necessary specifications for various plumbing, irrigation, and industrial applications.

For the best deals in SCH40 and high pressure SCH80 PVC Valves, you can check out 247Garden's ERA selections here. And if there's something you like for us to carry for you, please don't hesitate to reach out to us. You can always call or text us 323-318-2600. Our normal business hours are Monday to Friday 10AM to 5PM PST. Thank you