Date: November 19, 2024

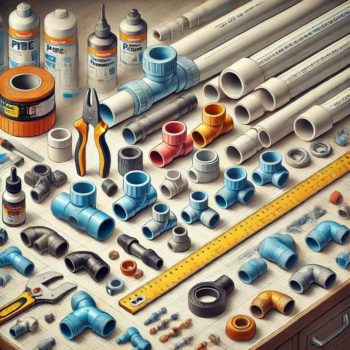

Finding the Right PVC Pipe for PVC Connectors: A Simple Guide

When working with PVC connectors and pipes, it's essential to ensure compatibility between the pipes and connectors to avoid leaks and ensure the system functions properly. Whether you're working on a plumbing project, building a DIY structure, or setting up an irrigation system, understanding how to select the right PVC pipe for your connectors can save you time, money, and frustration. Here’s a basic guide to help you choose the correct PVC pipe for your project.

1. Understand Pipe Sizing

PVC pipes come in various sizes, and it’s crucial to match the diameter of your pipe with the connector's size. The size of the pipe is usually listed in inches (e.g., ½", 1", 2"), and it refers to the nominal diameter, which is the internal measurement of the pipe.

- Nominal Size vs. Actual Size: Keep in mind that the "nominal" size (e.g., 1 inch) doesn't always match the exact measurements of the pipe. For example, a 1-inch PVC pipe typically has an outside diameter of 1.315 inches, and the inside diameter is smaller.

2. Know Your Connector Type

PVC connectors come in different forms, such as elbows, tees, couplings, and flanges. It’s important to choose connectors that are designed for the same size pipe. For example:

- A 1-inch PVC pipe will need 1-inch connectors, such as a 1-inch elbow or coupling.

- Connectors are typically labeled with their size (e.g., 1" slip, 1" thread), and it’s essential to match the pipe's outside diameter with the connector's inside diameter.

3. Pressure Rating

PVC pipes come in different pressure ratings, which indicate how much pressure the pipe can handle before it may fail. Common pressure ratings include:

- Schedule 40: Standard thickness, typically used for most plumbing and irrigation systems.

- Schedule 80: Thicker walls, ideal for higher pressure applications. Be sure to choose pipes and connectors with compatible pressure ratings for your project. For example, if you’re building a high-pressure system, you’ll need both Schedule 80 pipe and connectors, not Schedule 40.

4. Material of the Pipe

PVC pipes come in various grades, with the most common being PVC-U (Unplasticized). However, you may encounter pipes with additives for different environments or applications, such as those designed for UV protection, flexibility, or chemical resistance. Always consider the environment where your PVC system will be used.

5. Consider the Pipe Length

PVC pipes are sold in various lengths, and you can buy them in 10-foot or 20-foot sections, or even shorter lengths at some hardware stores. Measure the length you need for your project and cut the pipe accordingly. Most connectors are designed to fit with standard lengths of pipe, but always check the specifications before purchasing.

6. Cutting the Pipe

When preparing your PVC pipes for connectors, make sure to use the right tools. A pipe cutter or hacksaw can be used to cut PVC pipes, and it’s important to make clean, straight cuts to ensure a proper fit with your connectors. After cutting, remove any burrs from the edges to avoid damaging the connectors or creating leaks.

7. Assembly and Sealing

After selecting the right PVC pipe and connectors, it’s time to assemble the system. Use PVC primer and PVC cement to bond the pipe and connector securely. Follow the manufacturer's instructions for proper curing times, and ensure you apply the cement evenly to prevent leaks.

Final Thoughts

Choosing the right PVC pipe for your connectors is key to ensuring a secure, functional system. Always match pipe sizes and consider pressure ratings and material compatibility. With these tips, you can confidently select the right PVC components for your project and avoid common pitfalls like leaks or poor performance.

If you’re unsure about the specifics, ask your local hardware store for help or refer to product guides and technical specifications to make an informed decision. Happy building!